This article contains our technical opinions and is for general information purposes only.

The CE Code, in conjunction with the National Building Code of Canada, requires certain critical life safety circuits to be protected from exposure to fire for 1 to 2 hours depending upon the application. The rationale is to protect critical circuits to ensure they continue to operate long enough during a fire to evacuate buildings safely. This newsletter will introduce the options available to wire up these circuits and give insight into the ULc S139 fire test.

Figure 1: VITALINK® System

The CE Code allows 3 approved methods to protect conductors and cables in these critical circuits:

- Using cables passing ULc S139 with hose stream circuit integrity test

- Embedding a raceway with regular electrical conductors in concrete with a thickness sufficient to protect from fire for 1 hour (2 hours in some cases)

- Installing the raceway with electrical conductors in a shaft enclosure or service space of 1-hour minimum fire resistance construction (2 hours in some cases)

First, we should differentiate between fire-rated and flame-rated cables as they are often confused. Fire-rated cables (sometimes referred to as circuit integrity cables) are special cables designed to operate for a specified period of time in a fire. ULc S139 with hose stream is the fire test for both the CE Code and National Building Code reference for Canadian applications.

Flame-rated cables are tested to CSA flame spread tests like FT4. CSA FT4-rated cables are designed to self extinguish when outside the flame source, preventing the fire from spreading around a facility via the exposed cables. However, these cables will burn and fail to operate in most fire situations.

Fire-rated cable systems are required for life safety-critical circuits like emergency power supplies, emergency generators, fire alarms, fire pumps, emergency elevators, emergency lighting, smoke venting fans, and mechanical systems serving areas of refuge. These are detailed in the CE Code and National Building Code of Canada. Industrial facilities may require fire-rated cables for fire pumps, emergency shutoff valves, and critical instrumentation. Often Industrial facilities rely upon cable systems tested to even higher requirements than ULc S139, such as UL1709.

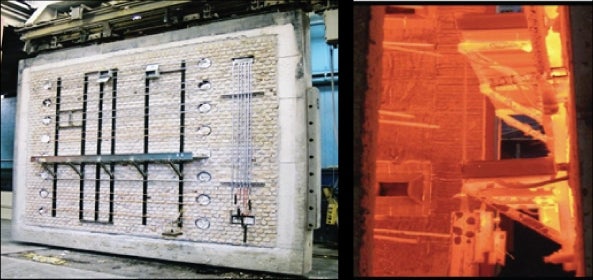

ULc S139 with hose stream is an extremely severe system test for circuit integrity cables. It is designed to ensure these critical cables are tested as the system would be installed, to levels that can be experienced in a real-life fire situation. The other two approved installation methods, fire-rated shafts, and concrete-encased systems, test only the components assuming they will work when assembled.

The cable system is tested both vertically and horizontally by installing it on a concrete block wall and heating it to 1850°F at 2 hours. Within 5 minutes of ending the fire exposure, the cable system is sprayed with a hose stream simulating a fire hose in a real fire situation. The cables are then reenergized and tested for circuit integrity.

Figure 2a) Cable System Set Up for Testing, 2b) Actual Test at 1010°C or 1850°F

All in all, this is an extremely harsh test showing the full system including supports and listed components can survive a typical fire for up to 2 hours. The test includes both heat as well as mechanical stressors from the fire hose. Testing it as a system removes some unknown factors that might cause real-world installations to fail prematurely.

A system test like ULc S139 is critical to give electrical designers confidence that their design will perform in an actual fire as compared to component-tested products that should work, in theory, when installed together. To ensure performance, these life safety products are ULc required to be installed with the same glands and support systems they were tested with as laid out in their corresponding ULc FHIT7 certificate.

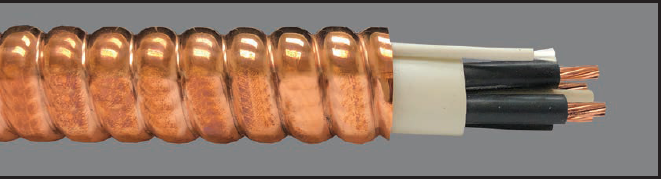

Figure 3: VITALink® MC Cable

Personally, Keith and I like the VITALink® product as it passes ULc S139 with hose stream as a system, meets CE code requirements, and installs like a “Teck” cable, which reduces contractor installation risk. For designers, a system-tested product that must be installed according to a system ULc FHIT document reduces some of the worries of how much detail they need to specify to ensure an installation will work. We all want these critical systems to perform as designed.

Texcan provides a complete end-to-end solution for 600 Volt Armored cable requirements as well as cables in conduit (CIC) solutions for 72v or less for life safety applications.

About the Author

Blair Sackney has 23 years of wire & cable experience gained through major industrial, infrastructure, and commercial projects across North America. As an active IEEE member, Blair is passionate about sharing his expertise on better and safer cable installations.

He can be reached by phone at 604-528-3622 or via email at Blair.Sackney@texcan.com.

Read our articles on fire rated cables for more information on 2-hour fire rated cables, Texcan Launches VITALink® MC 2-Hour Fire Rated Cable, Texcan Adds VITALink Low Voltage Offering, Texcan Now Stocking Comtran VITALink® Cable.